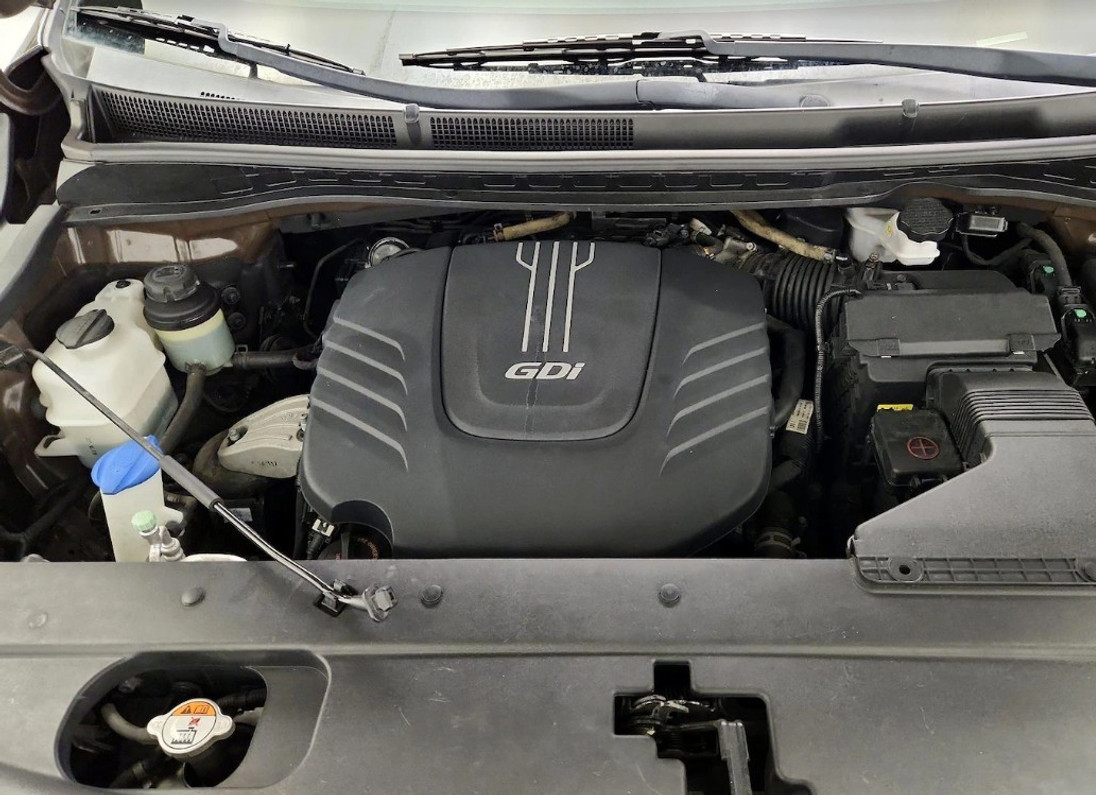

Head Bolt Stripping in Kia and Hyundai Engines: How Common Is It and How to Fix It

A customer recently emailed us with a great question: “What percent of Kia vehicles would you say have the head bolt stripped?” It’s a common concern for owners of Kia and Hyundai vehicles with 3.3L, 3.5L, and 3.8L engines and it’s no surprise why. Stripped head bolt threads in aluminum engines are a known headache, especially for models using M11x1.5 head bolts (like those compatible with Fel-Pro ES72366 head bolt). Let me provide a little more info on the issue and I'll share the best fix for it—spoiler alert: our Time Sert kits have you covered. How Common Are Stripped Head Bolts in Kia and Hyundai Engines? Unfortunately, there’s no official data from Kia or Hyundai that gives an exact percentage of vehicles affected by stripped head bolt threads. Without large-scale studies or manufacturer reports, it’s tough to nail down a precise number. That said, if you’ve spent any time on automotive forums or talking to mechanics, you’ve likely heard about this issue cropping up in certain models, here's a partial list including:

- Hyundai Azera (3.3L 2007–2017, 3.8L 2006–2011)

- Hyundai Entourage (3.8L 2007–2010)

- Hyundai Genesis (2009–2016)

- Hyundai Santa Fe (3.3L 2006–2019, 3.5L 2010–2012)

- Hyundai Sonata (3.3L 2006–2010)

- Hyundai Veracruz (3.8L 2007–2012, 2008–2011)

- Kia Sorento (3.3L, 3.5L, 3.8L, various years)

- Durability: The steel inserts are tougher than the original aluminum threads, reducing the risk of future failures.

- Precision: Time Sert kits are engineered for a perfect fit, especially for M11x1.5 head bolts used in these Kia and Hyundai engines.

- Versatility: Whether it’s a first-time fix (2200) or a rescue for a botched repair (2200BS), these kits are the go-to solution.

- Cost-Effective: Skip the dealership markup and fix it yourself with confidence.

- Installing a replacement block or engine means aluminum threads are still at risk of failing.

Time Sert thread repairs are considered permanent and should last the lifetime of the engine. Reduce the risk of thread failure with these tips:

- Proper Torquing: Always use a torque wrench and follow the manufacturer’s specs when installing head bolts. Replace TTY bolts when doing the job.

- Consider repairing all holes while the head is off, because the weakest point is likely to fail next.

- Regular Maintenance: Keep an eye on your temperature gauge and cooling system to avoid overheating, which can stress the bolts.

- Use Quality Parts: Stick with OEM or high-quality aftermarket bolts (like Fel-Pro ES72366) to ensure a secure fit, that meets the manufacturer's specs.

9th Jul 2025

Recent Posts

-

Why Your Time-Sert Driver Gets Tight Early

If you use Time-Sert kits frequently, you might be used to the insert screwing onto the driver almos …6th Feb 2026 -

Debunking Myths: Is Stainless Steel Just Carbon Steel with Rust Protection?

Hello, I'm Dennis Bandy, owner of Wise Auto Tools and a Master Automotive Technician with many years …15th Jul 2025 -

Head Bolt Stripping in Kia and Hyundai Engines: How Common Is It and How to Fix It

A customer recently emailed us with a great question: “What percent of Kia vehicles would you say ha …9th Jul 2025