Automotive A/C Basic Component Info - Tips for Techs

Wise Auto Tools - There are several key components in an automotive air conditioning (AC) system, each with their own function to ensure the proper operation of the system. Here are some of the key components and their functions:

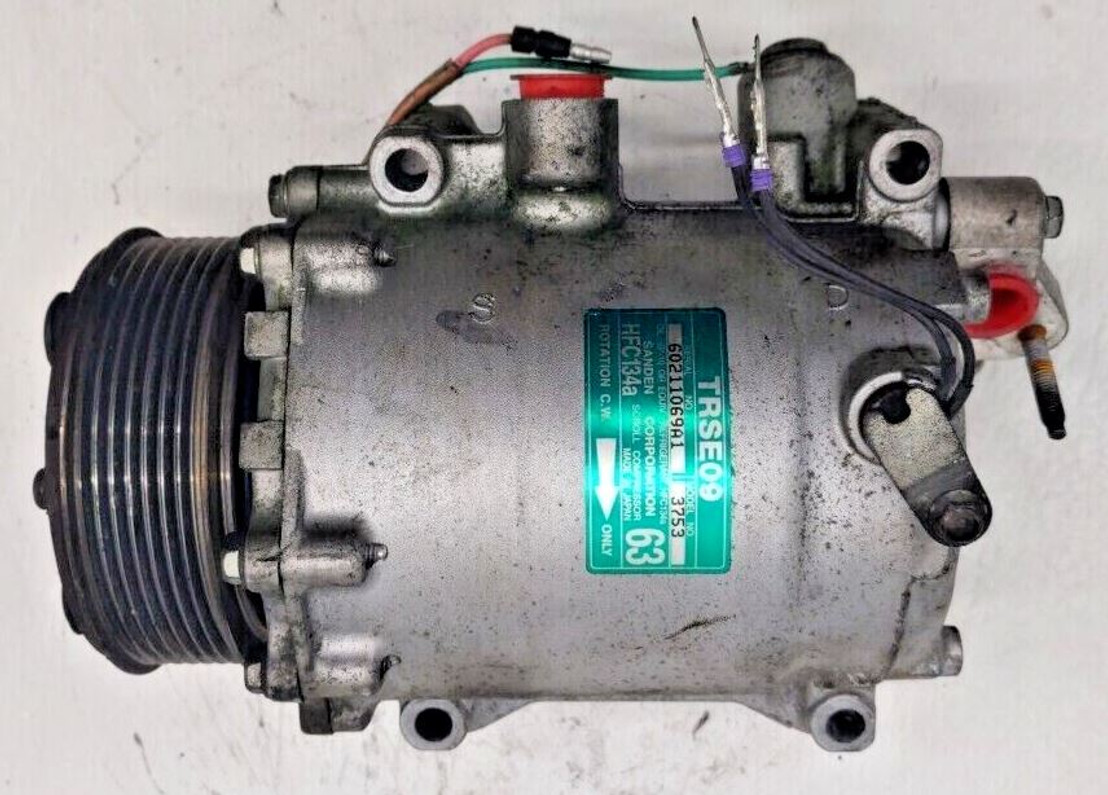

Compressor: The compressor is the heart of the AC system. It is responsible for compressing and circulating the refrigerant gas through the system. The compressor is driven by a belt connected to the engine, and it operates by taking in low-pressure refrigerant gas and compressing it to high pressure.

Condenser: The condenser is located in front of the radiator and is responsible for releasing the heat absorbed by the refrigerant during the cooling process. It works by converting the refrigerant gas into a high-pressure liquid, which is then cooled by passing air over it.

Receiver/Drier: The receiver/drier is a component that is responsible for removing any moisture and contaminants from the refrigerant gas. It is typically located on the high-pressure side of the AC system and acts as a filter to prevent any debris from circulating through the system.

Expansion Valve/Orifice Tube: The expansion valve or orifice tube is located on the low-pressure side of the AC system and is responsible for regulating the flow of refrigerant through the system. It works by restricting the flow of refrigerant, which causes a drop in pressure and a subsequent drop in temperature.

Evaporator: The evaporator is located inside the vehicle and is responsible for absorbing the heat from the interior of the vehicle. It works by converting the low-pressure liquid refrigerant into a low-pressure gas, which absorbs heat from the surrounding air and cools it.

Blower Motor: The blower motor is responsible for circulating the cooled air from the evaporator through the vents and into the passenger compartment of the vehicle. It works by drawing in air from outside the vehicle and passing it over the evaporator, where it is cooled and then blown into the passenger compartment.

These are the key components of an AC system and their functions. Each component plays an important role in the operation of the system, and any malfunction or failure can result in a loss of cooling performance or even a complete failure of the system. Regular maintenance and repair of these components can help ensure the proper operation of the AC system and keep the vehicle's occupants cool and comfortable, especially during hot weather.

Question - What's the difference between a Receiver Drier and an Accumulator?

Similarities:

Both components are used to remove moisture and contaminants from the refrigerant gas in the AC system. Both components have a filter element containing desiccant that traps and holds any particles or debris that may be circulating through the system. Both components are designed to help protect the AC system components from damage.

Differences:

An accumulator is typically located on the low-pressure side of the AC system, between the evaporator and the compressor, while a receiver/drier is typically located on the high-pressure side of the system, between the condenser and the expansion valve. An accumulator is designed to absorb any excess refrigerant that enters the system and prevent it from entering the compressor, while a receiver/drier is designed to remove moisture and contaminants from the refrigerant gas. An accumulator achieves its refrigerant-absorbing function by trapping and storing excess refrigerant in its housing.

Question - What is Desiccant and what material is used for auto A/C?

Desiccant is a material that is used to absorb moisture from the surrounding environment. In the context of automotive air conditioning systems, desiccant is used in the receiver/drier or accumulator to remove any moisture that may be present in the refrigerant gas.

There are several different types of desiccant materials that can be used in AC systems, but some of the most common materials include silica gel, activated alumina, and molecular sieve. These materials are highly effective at absorbing moisture from the surrounding air, and they are often used in conjunction with a filter element to remove any contaminants or debris that may be present in the refrigerant gas.

In an AC system, moisture can be a problem because it can react with the refrigerant and form acids, which can cause corrosion and damage to the system components. Moisture can also freeze and block the expansion valve or orifice tube, which can cause a loss of cooling performance or even a complete failure of the system.

By using a desiccant material in the receiver/drier or accumulator, any moisture that enters the system can be absorbed and prevented from causing damage. This helps ensure the proper operation and longevity of the AC system.

Question - Should a technician to take precautions against moisture intrusion prior to installing a receiver/drier or accumulator in an automotive air conditioning system?

Yes. Keep the drier or accumulator sealed until installation: If changing several components, install the drier/accumulator last so the system can be closed as soon as possible after it has been installed. This will help prevent moisture from entering the desiccant and reducing its effectiveness.

Use a vacuum pump to remove moisture: Soon after the installation is complete, the technician should use a vacuum pump to remove any moisture that may be present in the AC system. This will help ensure that the system is free of moisture and ready for use.

Question - Which make of automobiles have the most failures related to AC compressors?

It is difficult to point to a specific make of automobiles that have the most failures related to AC compressors, as there are many factors that can contribute to compressor failures. Some of these factors include the age of the vehicle, the quality of the compressor and other components, and the operating conditions of the AC system.

That being said, there are some makes and models of vehicles that may be more prone to AC compressor failures than others. For example, vehicles that are regularly driven in hot climates or used frequently for short trips with frequent AC usage may experience more compressor failures due to increased wear and tear on the system components. Additionally, some older vehicles may be more prone to compressor failures due to the age of the components and the wear and tear that they have experienced over time.

Question - Which is more likely to cause leaks in condensers - external damage from accidents or road debris, or internal corrosion caused by moisture mixing with refrigerant?

The leading cause of leaks in a vehicle's condenser is from internal corrosion. Condensers can fail due to both external damage and internal corrosion. External damage can occur from accidents or debris on the road, which can puncture or damage the condenser. This can cause refrigerant to leak out of the system.

Moisture can enter the AC system over time, and if it is not removed by the receiver/drier or accumulator, it can mix with the refrigerant and cause corrosion to occur within the condenser. This corrosion can cause small holes or leaks to form in the condenser, which can lead to a loss of refrigerant and reduced cooling performance.

Question - Is it more likely for an expansion valve to leak, stick closed or stick open?

While an expansion valve can experience several types of failures, it is more common for it to stick closed rather than to leak or stick open.

When an expansion valve sticks closed, it restricts the flow of refrigerant through the system, which can cause a decrease in cooling performance or even a complete loss of cooling. This can be caused by debris or contaminants in the system, or by the valve itself becoming stuck due to wear or corrosion.

On the other hand, it is less common for an expansion valve to leak or stick open. If an expansion valve leaks, it can cause refrigerant to escape from the system, which can reduce the cooling performance and potentially damage other components. However, leaks in the expansion valve are less common than leaks in other components, such as the compressor or condenser.

If an expansion valve sticks open, it can cause an excessive amount of refrigerant to flow through the system, which can result in poor cooling performance and potentially damage other components. However, this type of failure is less common than a stuck closed expansion valve.

Question - Why are evaporators usually hard to access?

Evaporators are often hard to access in automotive air conditioning systems because they are typically located inside the vehicle's dashboard, making them difficult to reach and service.

The evaporator is responsible for absorbing heat from the interior of the vehicle and transferring it to the refrigerant, which is then carried outside of the vehicle to be dissipated. To achieve this, the evaporator is typically located in the dashboard, close to the vehicle's interior air ducts.

Because the evaporator is located in a tight and often hard-to-reach area, accessing and servicing it can be a challenging and time-consuming task. To reach the evaporator, the technician may need to remove the dashboard or other interior components, which can be a complicated and delicate process. Additionally, the evaporator is typically located in an area that is not easily visible, making it difficult to diagnose and repair any issues that may be present.

Question - What are common blower motor problems?

Electrical Issues: Blower motors rely on electrical power to operate, and issues with the electrical system can cause problems with the blower motor. This can include issues with the wiring, connectors, fuses, relays, or switches that control the blower motor.

Motor Failure: Like all motors, blower motors can fail due to wear over time. This can be caused by a variety of factors, including age, use, and debris like leaves causing drag on the blower cage/blower motor.

Blower Cage/Wheel Damage: The blower wheel is the component of the blower motor that actually moves the air through the system. Over time, the blower wheel can become damaged or worn, which can cause it to vibrate or make noise. As mentioned above, leaves may enter through the fresh air duct and cause noise, vibration and ultimately blower failure.

Blockages in the Ductwork: Blockages in the ductwork can restrict the flow of air through the system and reduce the performance of the blower motor. This can be caused by debris, dirt, or other obstructions in the ductwork. Sometimes an HVAC door can come loose and entirely block airflow.

Faulty Blower Resistor: The blower resistor is responsible for controlling the speed of the blower motor. If the blower resistor is faulty, it can cause the blower motor to operate on just one or two speeds or not at all.

Moisture Damage: If moisture enters the blower motor, it can cause corrosion or damage to the motor and its components, which can lead to failure over time.

Question - Which cars or trucks have the most problems with evaporator leaks?

Any vehicle can have a bad evaporator, however in recent years GM trucks have been known to have evaporator leaks. Also Chrysler products including Jeeps have had a lot of evaporator leaks. Most problems with evaporator leaks can vary depending on the vehicle's age, usage, and maintenance history.

Evaporator leaks are a relatively common problem in automotive air conditioning systems, and can be caused by design flaws, corrosion, damage to the evaporator fins, or wear and tear on the system components. Evaporator leaks can also be caused by exposure to moisture within the system, which can cause corrosion or damage to the evaporator over time.

Question - How much money can an Automotive AC tech make in Florida?

The average salary for an Automotive AC Technician in Florida is around $45,000 per year. However, the salary range can vary depending on factors such as the technician's experience, level of certification, location within Florida, and if he's paid by the hour or for production based on flat rate book time. According to data from the Bureau of Labor Statistics, the bottom 10% of Automotive AC Technicians in Florida earn less than $28,000 per year, while the top 10% can earn over $66,000 per year. It's also best for an automotive tech to have other areas that he's proficient in since A/C work is somewhat seasonal, even in Florida!

For many years, Wise Auto Tools has been selling automotive A/C tools and providing valuable information to customers. Be sure to bookmark our website and keep us in mind for all your future tool needs.

Recent Posts

-

Why Choose Wise Auto Tools for 38900/389XL Spark Plug Thread Repair Kits

When it comes to repairing spark plug threads, quality and reliability are paramount. At Wise Auto T …19th Jun 2024 -

Car A/C System Diagnosis and Air Conditioning Service Guide

This article is also available in video format at the bottom of the page.Car manufacturers started u …28th May 2024 -

Can the Time Sert 1115 kit be used for head bolt thread repair?

The short answer is a qualified yes, in some applications. The Time Sert 1115 kit is designe …14th May 2024